|

|

6) Designs and Processes for Glass

|

|

|

Designs and Processes page 3 of 3

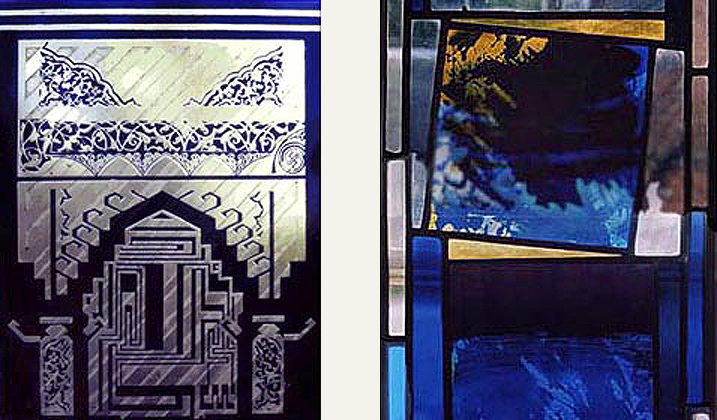

Two examples of acid etching on flashed glass.

Paint, stain and enamel must be kiln fired at different temperatures.

After soldering leaded lights must be cemented on both sides, dusted, dried and cleaned.

Where required the agreed price includes hire and errection of scaffolding, removal of existing glass, and use of temporary security boards.

Last stages:

New glazing bars go into the original bore holes, then the panels are slotted in and mortared. Copper wires hold the panels to the bars.

A Different Approach:

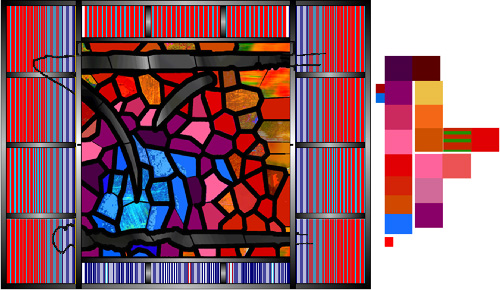

Imagery for the Nanoscience Department of Cambridge University features the logo, which combines flat shapes and brush calligraphy, and schematically represents the active point of an atomic force microscope

.

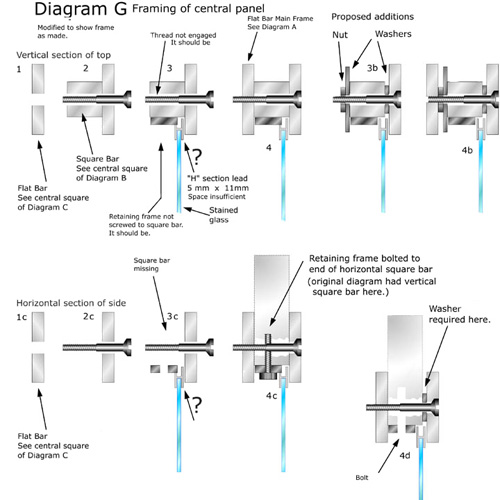

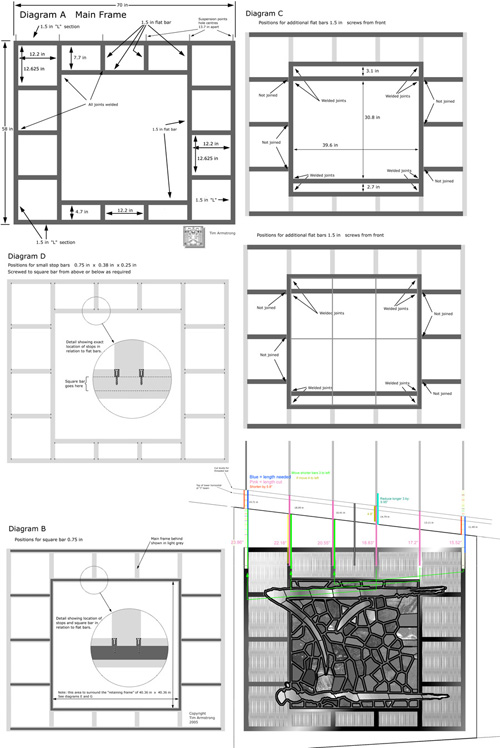

The frame was planned to scale. Early designs here highlight problems that had to be solved before finals sent to Metal Fusion Technology Ltd. who manufactured the frame in welded aluminium to accommodate additions in steel to hold the leaded lights.

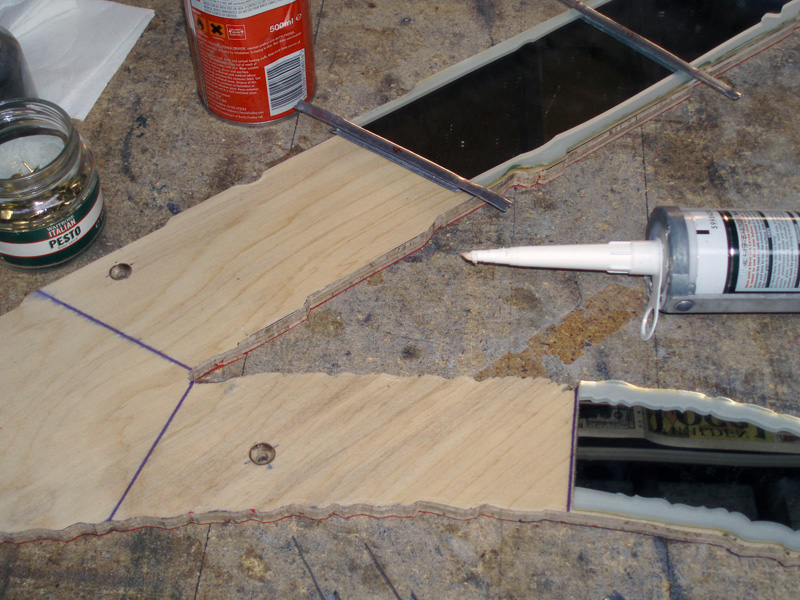

The shape of the calligraphy cut from plywood with bolt holes to attach to the main frame. Mirror treated with sealants, adhesives and fastened with lead cames.

Designs and Processes page 3 of 3

|

|

6) Designs and Processes for Glass

|

|

|

End of this Page

**

Back to top **Website designed by Tim Armstrong ©